Biomass Automatic Slag Burner Docking Boiler System

4. Second Combustion Chamber

4

Second Combustion Chamber

Advantages & Features

Haiqi Focus on Alternative Energy Services,Customized solutions for long-term operations and maintenance for projects of all sizes.

(1).jpg)

Long Service Life Of System

1.The whole body is poured with first-grade high aluminum refractory material, the main engine adopts 4 layers of protective measures, and the whole body is cooled by water.

2.Professional refractory casting process, anchor nail reinforcement, reasonable expansion joint process.

3.The top of the furnace is protected by 4 layers of American refractory material, and the top cover is water cooled and insulated.

4.The muzzle is made of imported high aluminum material, resistant to scouring and high temperature.

5.Outer used water jacket protection, reduce the furnace surface temperature, fully protect the furnace body.

High Efficiency Of System

1.The main body adopts three layers of insulation, less heat loss, improve heat utilization.

2.High temperature pyrolysis multi-stage vortex aeration to ensure full combustion of raw materials and improves thermal efficiency.

3.Suspension semi-gasification combustion, increase the contact area with oxygen, so that the fuel combustion is fully uniform, the overall thermal efficiency of up to 85%.

More Secure System

1.Before and after the furnace, the system can be interconnected and interlocked, anti-debursting and anti-tempering.

2.System micro negative pressure operation, simple operation of one person on duty.

3.The furnace body is equipped with a display temperature, which can be observed at any time, to avoid high temperature damage to the furnace body and the danger of scalding operators.

High Return On Investment, More Saving Cost

1.The cost of biomass fuel is low, only 20%-30% of diesel and natural gas, automatic control saves labor costs, scientific and technological design efficiency is high, and the comprehensive energy saving effect is obvious.

2.Environmental protection standards, biomass fuel emissions are almost zero pollution, sulfur dioxide and nitrogen oxide are far lower than the national emission standards.

3.Recovery cost is fast, investment of tens of thousands of yuan, annual savings of millions.

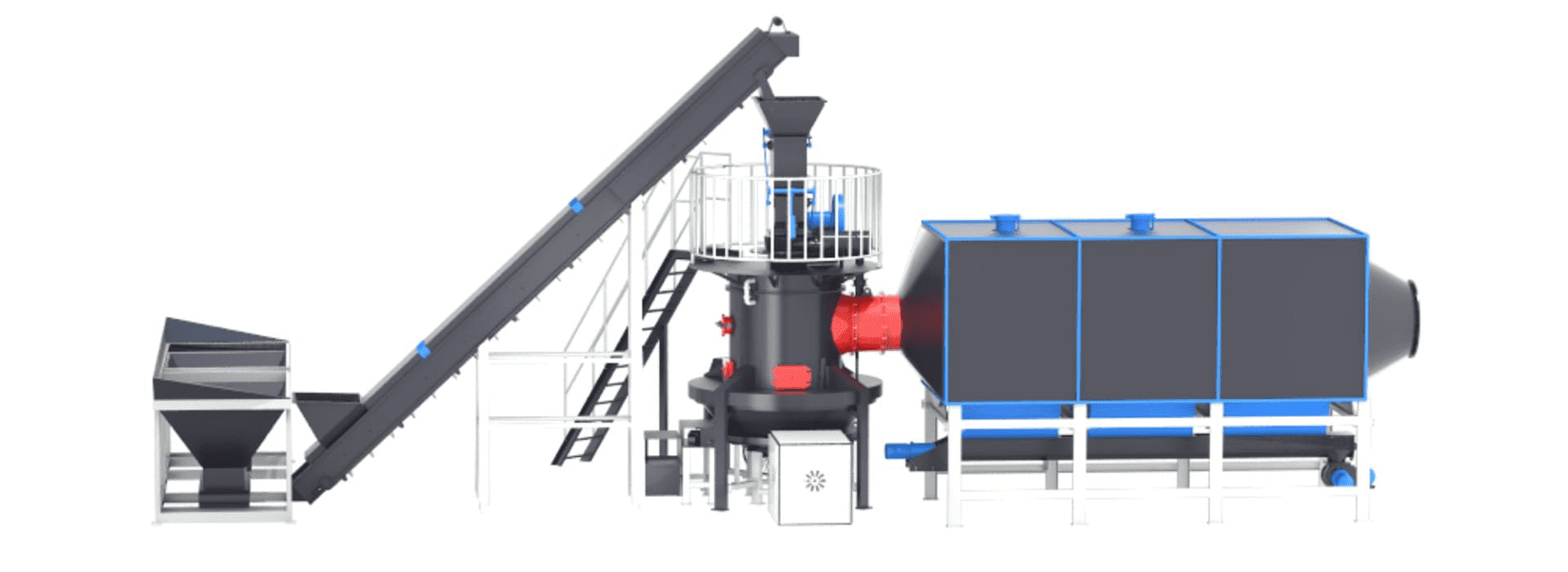

Biomass Automatic Slag

Burner Docking Boiler System Flow Chart

A biomass automatic slag burner uses renewable biomass energy as fuel to realize sustainable utilization of energy.

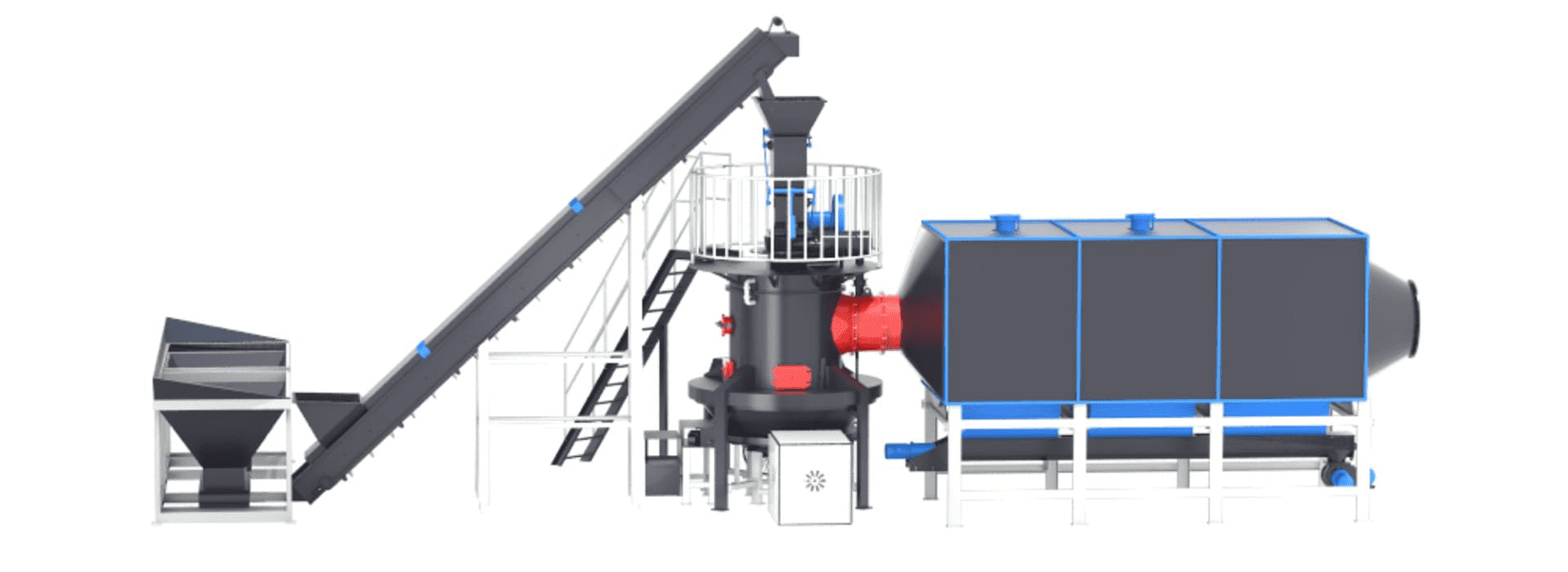

Biomass Automatic Slag

Burner Docking Boiler System By-Product Drawing

Biomass automatic slag burner uses renewable biomass energy as fuel to realize the sustainable use of energy.

Parameters Of Biomass Automatic Slag Burner

Parameters Of Biomass Automatic Slag Burner

| Model |

Rated Thermal Power (10⁴kcal) |

Rated Voltage V |

Input Power KW |

Fuel Consumption Kg/h |

Matching Boiler T |

Dimensions L*W*H |

Outer Diameter Of Burner mm |

Outer Diameter Of Burner mm |

Shipping Weight T |

| HQ-LM-SC2.0 |

120 |

380 |

6 |

400 |

2 |

3000*3000*5100 |

700 |

2200 |

5 |

| HQ-LM-SC4.0 |

240 |

380 |

11 |

800 |

4 |

3200*3000*6000 |

900 |

2730 |

9 |

| HQ-LM-SC6.0 |

360 |

380 |

15 |

1600 |

6 |

3600*3200*6700 |

1000 |

3410 |

12 |

| HQ-LM-SC8.0 |

480 |

380 |

29.5 |

1600 |

8 |

3800*3600*7100 |

1150 |

3460 |

20 |

| HQ-LM-SC10.0 |

600 |

380 |

40.5 |

2000 |

10 |

4300*3800*7300 |

1150 |

3460 |

25 |

| HQ-LM-SC15.0 |

900 |

380 |

52 |

3000 |

15 |

4500*4000*7300 |

1300 |

3600 |

30 |

| HQ-LM-SC20.0 |

1200 |

380 |

67 |

4000 |

20 |

5000*4200*7800 |

1500 |

3600 |

40 |

Biomass Automatic Slag

Burner Application Diagram

Haiqi biomass automatic slag burner are widely used in boilers, die-casting machines, industrial furnaces, incinerators, smelting furnaces, kitchen equipment, drying equipment, food drying equipment, ironing equipment, painting equipment, road construction machinery, industrial annealing furnaces, asphalt heating equipment and other thermal energy industries.

Biomass Raw

Material Types

Biomass automatic slag burner is non-polluting and has obvious environmental protection benefits. It uses renewable biomass energy as fuel to achieve sustainable use of energy.

Get Free Solution

We provide medium and long-term solutions to the problems of biomass waste, transforming waste into energy at no environmental cost and making it economically viable and at the same time compatible with the international environmental regulations and standards

Get More Product Information For Free

Fill in your contact information

Within 24 hours

Engineers get in touch with you

.jpg)

.jpg)

(1).jpg)

(1).jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.png)

.png)

.png)

.png)

.png)

.png)

.png)

.png)

.png)

.png)

.png)

.png)

.png)

.png)